Innovative Manufacturing Technology

About Innovative Manufacturing Technology

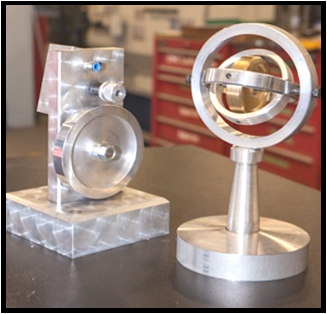

The Innovative Manufacturing Technology program teaches you how to create a wide variety of precision working parts by using different machines and hand tools to shape metals.

Students in Innovative Manufacturing Technology will develop the following skills:

– competent, safe and precise use of common machine shop equipment and tools

– effective use of 3D-Printers

– programming of Computer Numerical Controlled (CNC) Machines

Who Should Enroll?

Innovative Manufacturing Technology is looking for students who like fast-paced environments, working as part of a team, and designing their own projects. Students in this vocation are active participants in their learning, creative, and logical thinkers.

Employment Opportunities

Students who successfully complete Innovative Manufacturing Technology will enter the workforce as a level 2 apprentice machinist, CNC operator, or machine shop helper. Competency in machining technology is a great skill for those interested in pursuing careers in engineering.

Additional Information

Curious about how things are made? Do you imagine objects that don’t exist yet? Problem solving and methodical thinking are two important components of the machinists’ craft. Students in this program develop their ability to imagine the steps necessary to move objects from the idea to production stage.

Course Listing

Grade 9 (.5 Credit) MEHR1G

This course is intended for students who wish to sample Machining Technology. Students develop skills and knowledge necessary to perform basic calculations, basic machine and work set-up, and basic cutting of material in a safe, efficient, and responsible manner through the application of practical projects. An appreciation for the machining program is fostered through a safe, active, exciting, and informative learning environment.

Grade 10 (1 Credit) MT841V1S

Students will learn an introduction to technical drawing interpretation, hand tools, layout techniques, drill press operation, band saw operation, precision measurement, lathe operation, quality control and computer numerical control (CNC) programming, set-up operation and more.

Grade 11 (4 Credits) MT000V30

Students will learn safety, advanced technical drawing interpretation, advanced lathe operation, introduction to milling machines, advanced quality control and advanced CNC programming set up, operation and more.

Grade 12 (4 Credits) MT000V40

Students will have the opportunity to improve their skills on all machine shop equipment as well as advanced milling operation, expert advanced lathe operation, expert advanced CNC programming, set-up and operation. There is also opportunity for work experience during the year. Time is taken to prepare students for their transition from high school to work or post secondary education.

Contact Information

HALLDORSON, Mr. Vance – vhalldorson@wsd1.org